- Ferrite Microwave Technologies's High power microwave tempering system boasts the world's fastest tempering speed.

Microwave Tempering Oven & System

strength

20°C

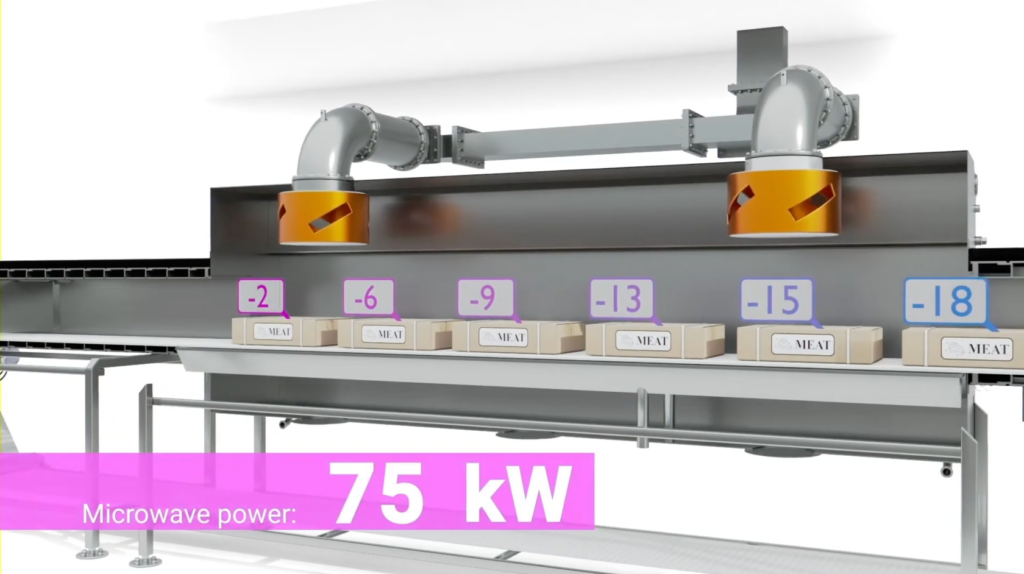

Our microwave tempering system defrosts frozen products to -3°C from -20°C quickly. It keeps freshness and preserve the taste with no dripping.

1,500 pounds

The MIP4 oven by Ferrite Microwave Technologies tempers up to 1,500 lbs (680 kg) of food per hour, ideal for meats, fish, fruits, and baked goods.

40+ years

Ferrite Microwave Technologies excels in high-power microwave devices, offering over 40 years of expertise in circulators and isolators.

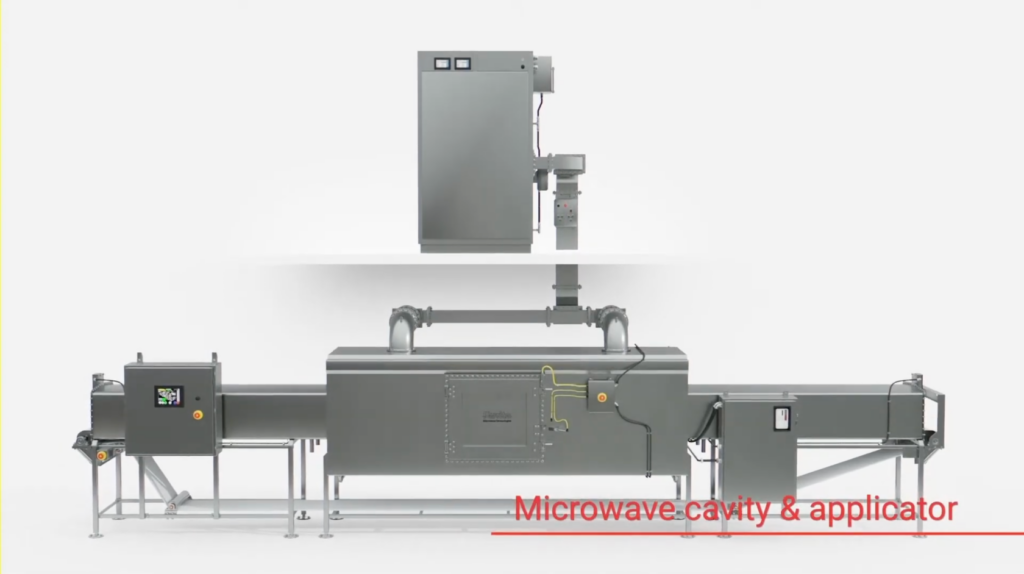

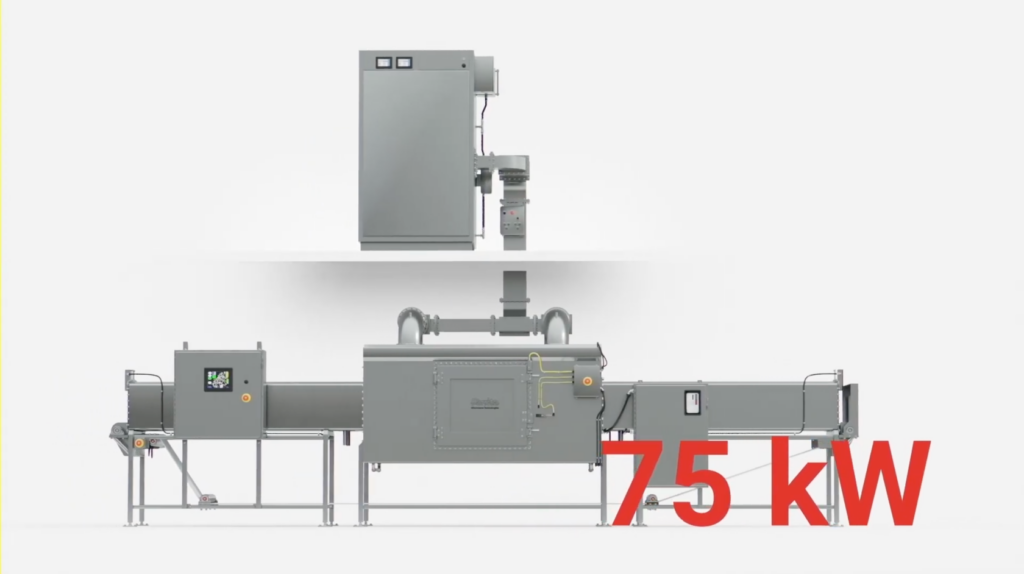

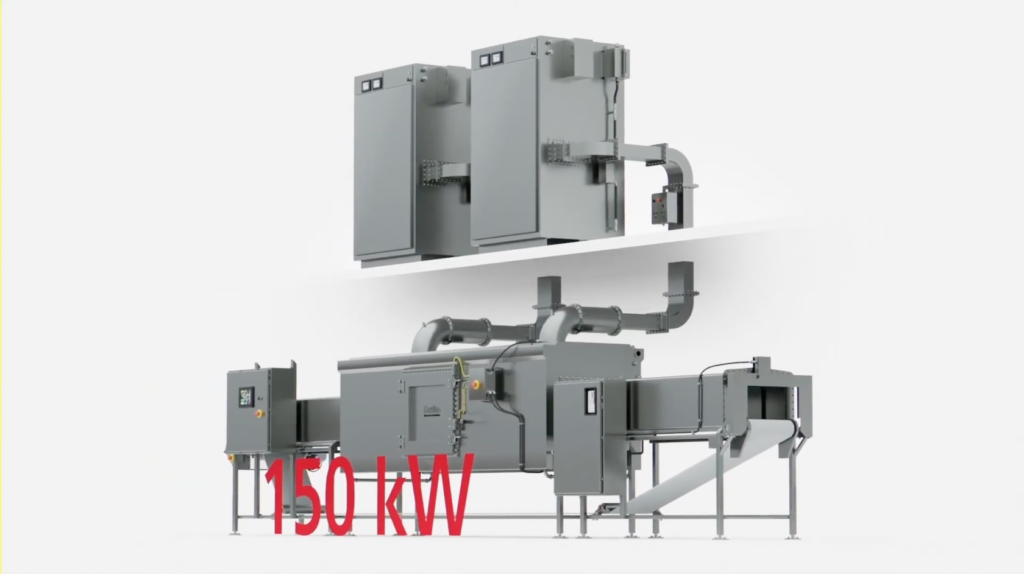

- MICROWAVE TEMPERING TUNNEL OVEN SYSTEM - MIP12

The high-power microwave tempering system features the world's fastest tempering speed.

High speed tempering methods contributes to labor cost reduction and also effective in reducing water consumption.

Usage Scenes

Product Introduction Video

- Products

Microwave Tempering Oven & System

Mini Batch Microwave Tempering Oven - MIP4

Ferrite Microwave Technologies mini batch microwave tempering oven (MIP4) is for food processing applications that need to temper on demand. It is ideal for meat, chicken, fish, fruit, and bakery products.

This mini batch microwave tempering oven can temper up to 1,500 pounds (680 kg) of raw, frozen product per hour.

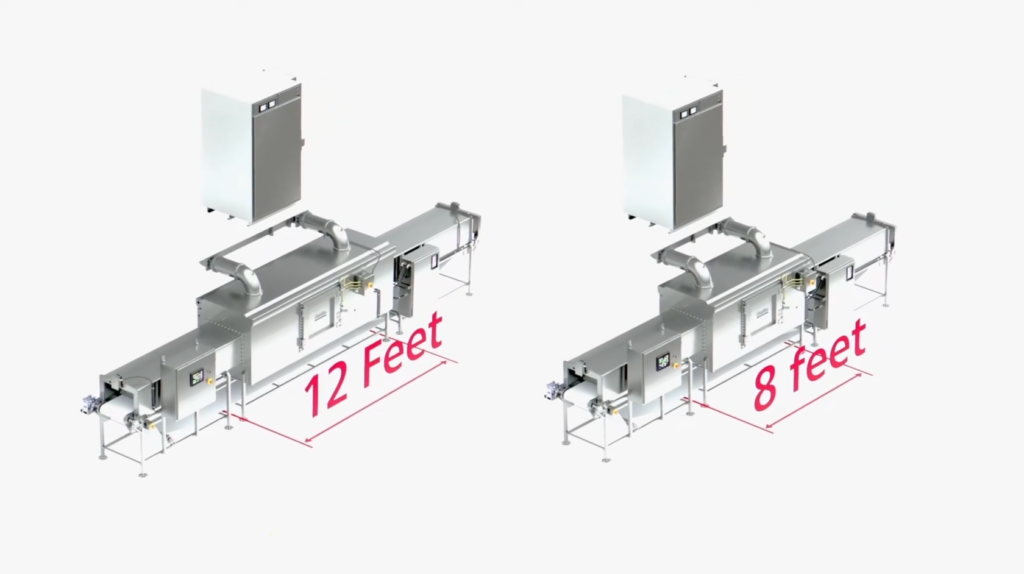

Microwave Tempering Tunnel Oven System - MIP12

ISO 45001:2018 sets rules for creating a robust occupational health and safety management system. It guides organizations to ensure safe workplaces, prevent injuries, and improve OH&S performance.

Ferrite Microwave Technologies.

Ferrite Microwave Technologies, A Microwave Technology Company, is the leading global provider of high-power microwave circulators and isolators.

For 40+ years, Ferrite’s waveguide and coaxial components have provided unique capabilities in protection and detection. ‘s expertise is in the manufacture and design of high-power passive microwave devices. https://ferriteinc.com/

Exclusive distributor in South-East Asia

Meiji Machine Co.,Ltd is an exclusive distributor of Ferrite Microwave technologies LLC’s microwave tempering oven system in Thailand, Vietnam, Malaysia, Indonesia and Japan.

FAQ

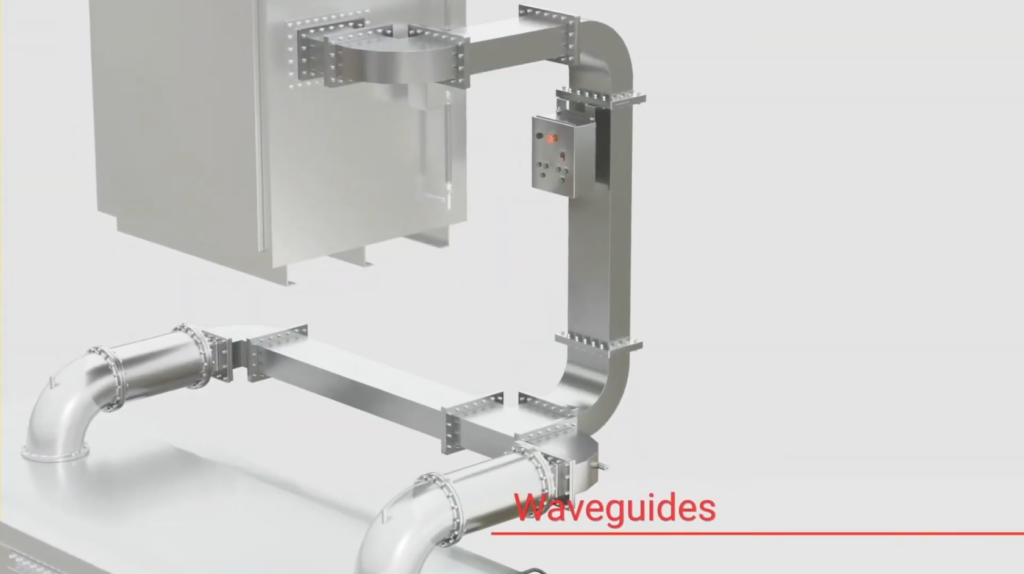

What are some unique features of the MIP12 tempering tunnel?

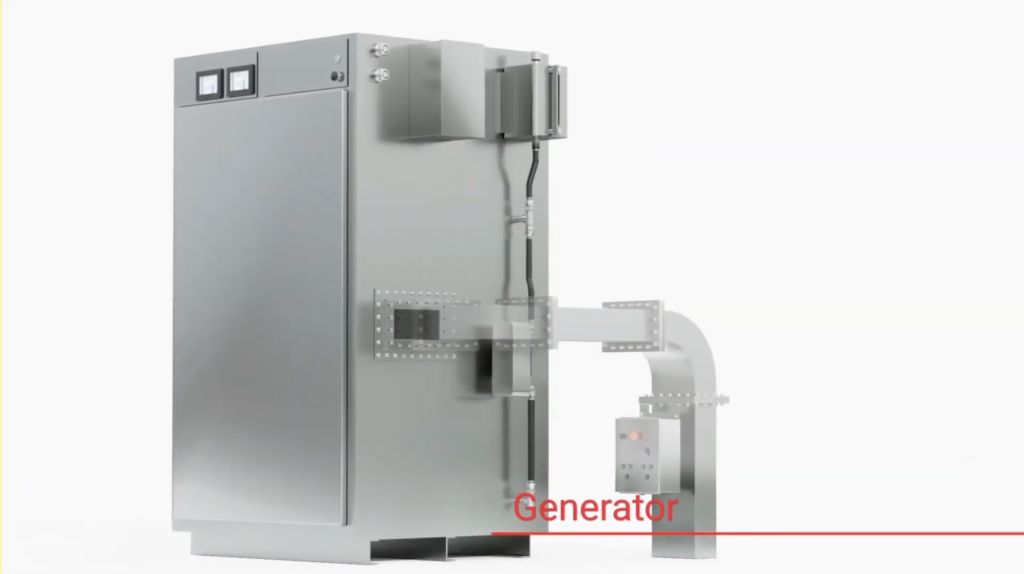

The MIP12 features some of the most advanced microwave system technology in today’s world.

This includes: user-friendly FMT system software, Allen-Bradley controls, and remote troubleshooting capabilities, to name a few. The unit also features arc detection, emission sensors (on either end of the tunnel), and safety interlocks on the door.

Is FMT microwave system equipment safe?

Yes. As a matter of fact, it exceeds most safety standards.

Our equipment conforms to safety exposure limits of 5 mw/cm² measured 5 cm away from equipment. This is twice as stringent as OSHA’s voluntary standard.

What is the general size of products that fit into the tempering tunnel?

The standard tunnel accommodates boxes 20″ x 10″ (50 cm. x 25 cm.).

However, other tunnel sizes are also available.

What are typical applications of the mini batch tempering oven?

Typical food processing applications include around-the-clock tempering of a wide variety of products.

Often, we see ovens such as the MIP4 best suited for low to mid volume, continuous flow applications, such as a cruise ship galley.

What are some of its safety features?

Interlocking access doors on the generators meet all applicable government (OSHA and Health & Human Services) safety standards, and provide the safest operating environment available.

Fittings can be provided to the oven to interface with an optional, customer-supplied fire suppression system. Customer supplied light and temperature sensors may be used in the oven to send signals to trigger the system.

Is a warranty available?

The MIP4 mini batch microwave tempering oven is warrantied for a period of one year.

However, FMT offers both in- and out-of-warranty service support, handled by our certified field technicians.

view more